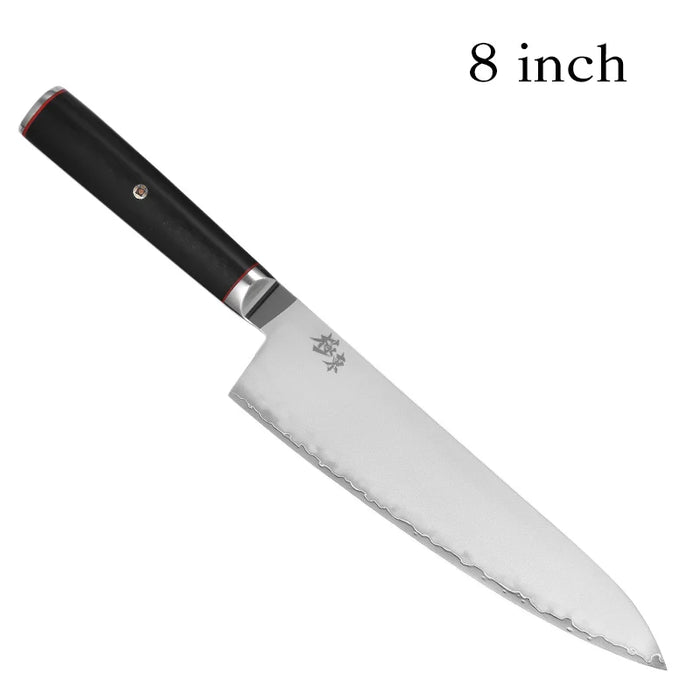

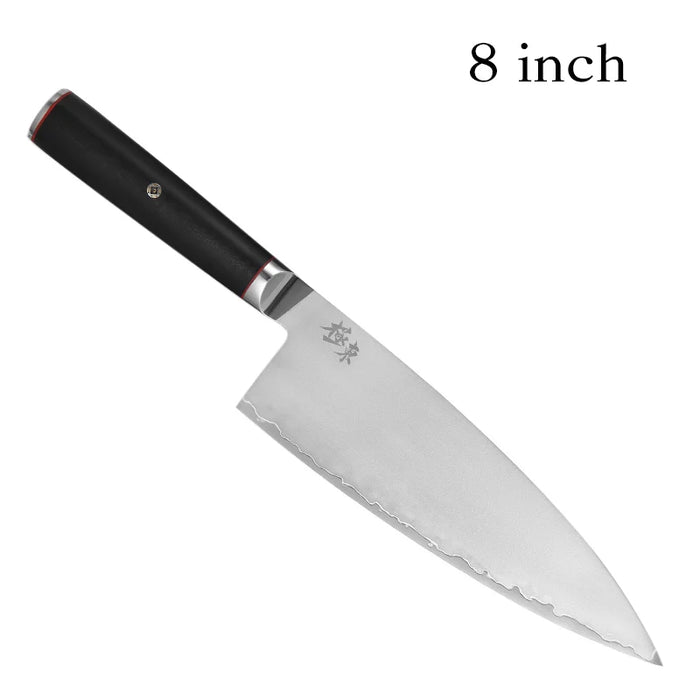

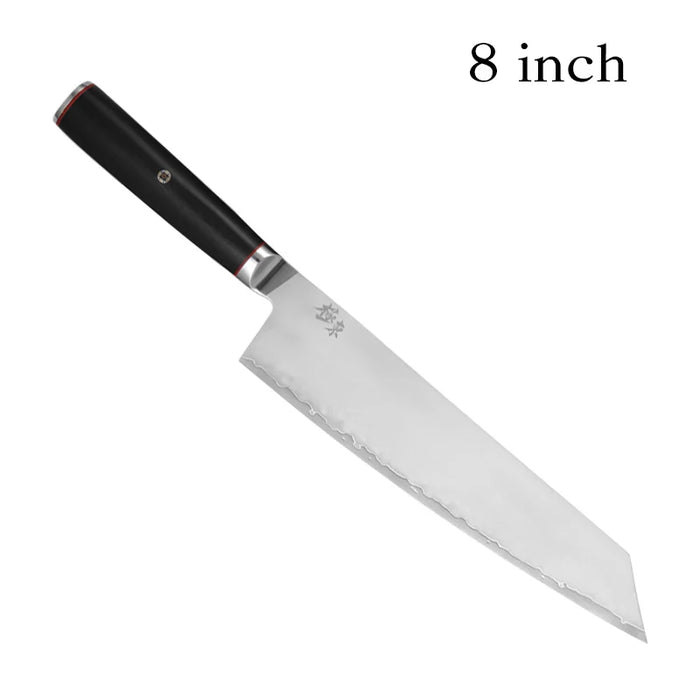

Japan AUS-10 composite steel Forging knife Cleaver Chef Gyuto Filleting Knives Santoku Boning Paring Utillty Seiko knife

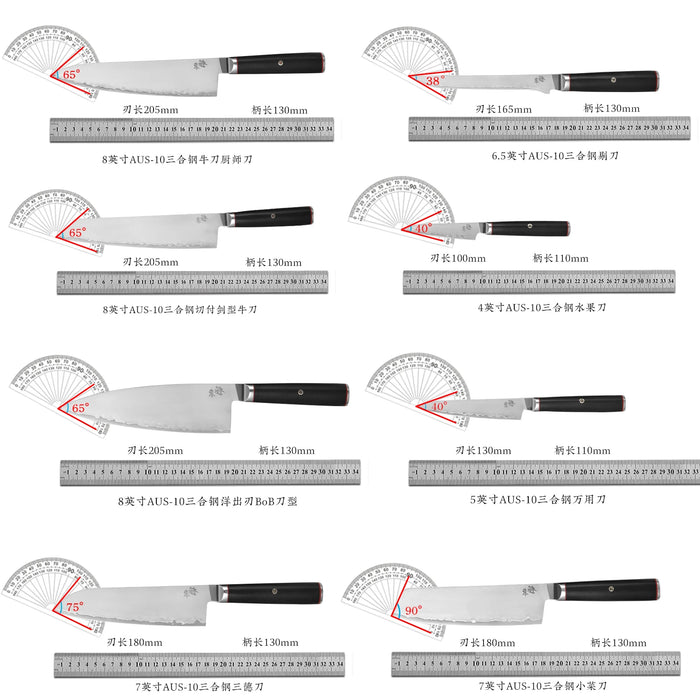

SPECIFICATIONS

- Brand Name : NoEnName_Null

- Blade Length : 23

- Blade Material : Alloy

- Sharp Blade : YES

- Blade Angle : >60°

- Handle Length : 14

- Origin : Mainland China

- Type : Knives

- Model Number : AUS10

- Certification : CIQ

- Certification : SGS

- Knife Type : Petty Knives

- Material : AUS-10

- Measurement unit : 100000015

- Sold in : sell_by_piece

- each pack : 1

- Package size - height (cm) : 6

- Package size - length (cm) : 43

- Package size - width (cm) : 10

- Package weight : 0.600

This product tool raw materials imported from Japan AUS-10 composite steel, with Chinese law recognized customs import and export documents and formal material source contract documents, produced by Chinese professional knife maker,"competitive price to meet unparalleled service, to provide customers with comprehensive satisfaction experience"

Japanese AUS-10 composite steel forged kitchen knife

Please read the following instructions carefully before purchasing:

1. Free Solid Wood Knife Cover

Depending on the type of knife purchased, we offer solid wood knife cases.

Product performance introduction:

1. Quality Materials:

This product adopts Japanese AUS-10 composite steel, which has excellent performance and can ensure the hardness, toughness, sharpness and durability of kitchen knives.

2. Blade design:

At a blade angle of 15°, use sharp kitchen knives to handle delicate kitchen ingredients. A sharp kitchen knife will not damage the fiber structure of the ingredients, nor will it affect the taste of the ingredients. Without crushing the whole tomato. A dull knife is far more dangerous than a sharp one.

3. Steel core hardness:

The hardness of steel core of kitchen knife is HRC60±2. High-quality steel can ensure the stability of product hardness and improve durability.

4. Forging process:

The product is forged from 3.5mm thick steel. After many forging, the blade gradually becomes thinner, from 2.2mm to 1.7mm, which can not only achieve sharpness, but also reduce the weight of the blade.

5. Material testing:

The Swiss SGS authoritative testing agency test, the product metal content reaches the standard, carbon content is 1.01%, chromium content is 14.9%, molybdenum content is 0.90%, vanadium content is 0.28%. Good steel is the basis for making quality tools.

6. Sharpness test:

The product has been tested to razor standards below 100N, and the average sharpness of kitchen knives is 210N. After special treatment, kitchen knives with mirror edge and high definition can be produced.

7. Forging process:

The forged blade highlights the beautiful ripple lines of the blade, showing the Japanese precision burning blade lines.